How long does it take to fix a hole in plaster?

When there’s a hole in the plaster in the wall, it can take only a couple of minutes to repair. However, this does not include preparation and drying time. Fixing a hole requires a bit of precision and using the right tools to ensure the job is completed correctly. You’ll need to be open to repeating the process to ensure it’s reinforced correctly to avoid potential problems.

Materials and tools

- Wall repair kit

- Dust mask

- Safety glasses

- Putty knife

- Trimming knife

- Paint scraper with a wide blade

- Sandpaper

- Rag

- Plaster compound

- Jointing tape

- Cork sanding block

How to patch a hole in the wall

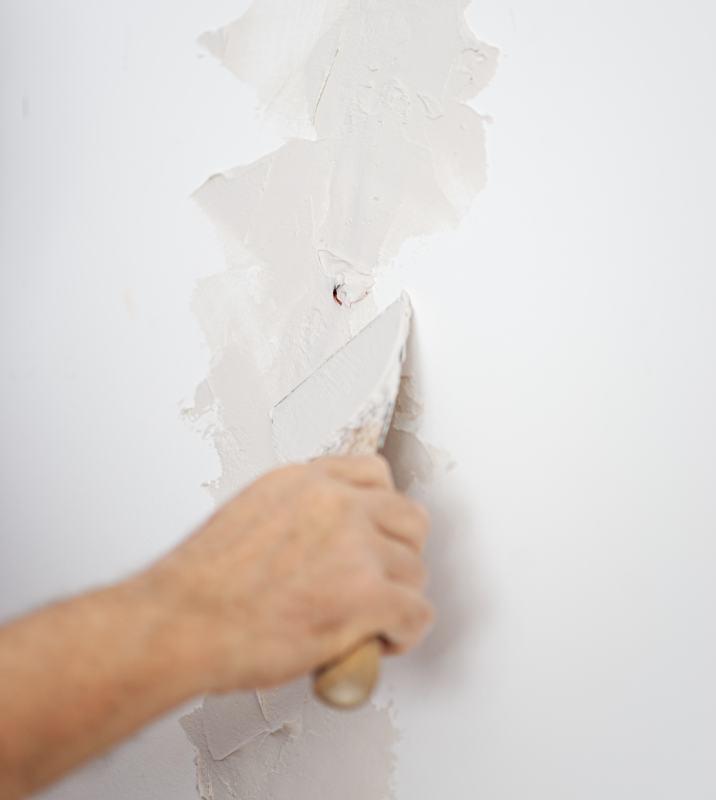

- Clean the area: When you want to repair a hole in plasterboard, start by cleaning around the hole to remove any loose debris that may be present. Any small pieces of dust or particles can get stuck in the plaster and can prevent the surface from looking smooth once it dries. Tap down the edges of the hole with the handle of your putty knife and scrape around it to make it smooth.

- Apply mesh: Peel off the back of a square piece of adhesive fibreglass mesh and secure it firmly over the hole when plastering holes in walls. There should be two to three extra centimetres of the mesh material around the hole to ensure there’s sufficient coverage. You can then add some adhesive tape to secure it.

- Apply plaster: Use plaster compound to fill the hole while sanding the surrounding paint to roughen it up. Use jointing tape to reinforce the hole and add a little more compound before it starts to dry. Learning how to prepare the hole and the surrounding surface can allow you to get the best results.

- Sand down: Use fine paper to sand down the patched area and smooth it out for a clean, professional finish.

- Apply a second coat: After the first coat of plaster is dry, you can apply a second coat after lightly sanding it down and dusting the surface off with a clean rag. The second coat of hole filler should be slightly wider than the first coat and can be smoothed out with your paint scraper. Dust the surface off before you start to apply the first coat of paint to ensure it blends in well with the wall.

How to fix a large hole in plaster wall

You can repeat the process of repairing a hole in a plaster wall when you have a larger hole but may need more wall filler and a larger piece of fibreglass mesh. When you’re ready to perform plaster hole repair, measure the hole in advance and add a few centimetres before cutting the material to the desired size. Consider doing multiple coats to prevent the hole from forming again in the future.

How to patch a hole in the ceiling?

When you have a hole that is present in a ceiling where there’s plaster, the process is slightly different compared to plastering a wall. Start by accessing the attic to inspect the hole if it’s larger than 30cm wide. Move any nearby wires away from the hole, or call a professional if you don’t feel it’s safe to do it yourself.

Use a drywall knife to cut the damaged area out of the hole. Measure the amount of drywall that you removed to get an idea of how much mesh wall material and drywall type you’ll need to use to get proper coverage. Secure the mesh material with tape. Apply a thin layer of compound over the materials and allow it to dry before moving on to the next step.

You can now sand down the patched seams and wall hole filler with a fine-grit sanding block. More compound can be applied to the recessed seams in multiple layers, if necessary.

Contact local plasterers

How to hire a plasterer

Licencing and qualifications

After looking for a qualified professional and narrowing down your options, you’ll need to look into the background of each plasterer you’re considering hiring for the task. Look up the plasterer’s license to verify they’re qualified to perform the job and can legally perform the work. You can also inquire about their experience in the industry to determine if they can complete the task correctly.

Read online reviews

Search for reviews online to read about former clients’ experience working with the plasterer to determine if they recommend the services to other people. You’ll take less of a risk with the professional you hire if you get an idea of the quality of work they perform and if they have good interactions with their customers. The reviews will offer insight into the reputation of the individual in the industry.

Request a quote

The cost of patching holes in plaster is one of the main factors to consider when deciding who you plan to hire to perform the work. Avoid hiring someone who gives you the lowest quote, which means they may cut corners or don’t have as much experience in the industry compared to other professionals. Although you may pay more, it can allow the work to blend in more with the wall and for it to last long-term without caving in again.